| pcb version of the production of a process is how |

| 送交者: 小蛋糕 2023年10月24日00:17:50 于 [教育学术] 发送悄悄话 |

|

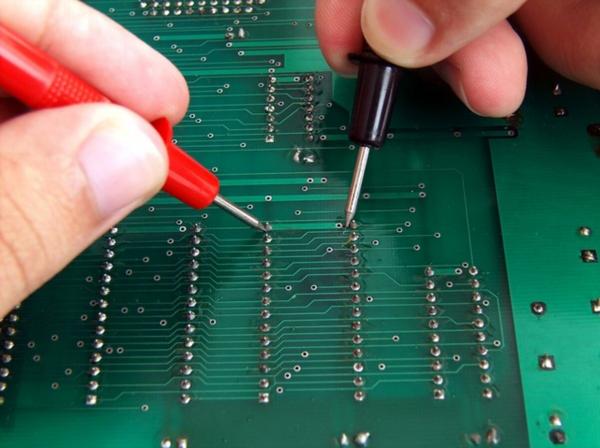

With the rapid progress of modern technology, PCB is also changing, but in principle the same estimate is the production process of PCB, the production of specific steps, here is a small series for you to analyze:. 1. Printed circuit boards. It is the printed circuit board will be printed on transfer paper, here it should be noted that the slip side to face themselves. Usually print two printed circuit boards on a piece of paper, choose the best printed one to make the circuit board. 2. Copper-clad board cutting What is a copper-clad board? There is a copper film covering both sides of the circuit board. Copper-clad boards are cut with photosensitive laminates to make circuit board diagrams.multilayer pcb fabrication Cut the laminate to the size of the circuit board, be careful not to cut too large, waste of material. 3. Pre-treatment of copper-clad laminates Copper cladding board surface oxide layer needs to be polished with fine sandpaper to ensure that the circuit board transfer thermal transfer paper toner can be firmly printed on the copper cladding board. (The polished surface should be bright, without obvious stains). 4. Transfer the circuit board Printed circuit boards cut into a suitable size of the enterprise, the printed design of the circuit board can be attached to the side of the copper-clad plate, aligned between the copper-clad plate into the thermal transfer machine, into the must be able to ensure that the transfer paper does not carry out the misalignment. General transfer 2-3 times, the circuit board technology can be very strong transfer in the copper-clad board. Warm tips:PCB factory the heat transfer machine needs to be preheated, the temperature is set at 160-200 degrees Celsius, because the temperature is very high, so pay attention to safety when operating! 5. Corrosion of circuit boards and reflow oven. First need to check whether the circuit board transfer is complete, if you find some bad transfer can be repaired with a black grease pencil, after corrosion. When the exposed copper film on the circuit board is completely corroded, the circuit board is removed from the corrosive solution and cleaned. The circuit board is thus corroded. Composition of corrosive liquid:Concentrated hydrochloric acid:Concentrated hydrogen peroxide:Water= 1: 2: 3. When preparing corrosive liquid, drain the water before adding concentrated hydrochloric acid and concentrated hydrogen peroxide. If concentrated hydrochloric acid, concentrated hydrogen peroxide or corrosive liquid is accidentally splashed on the skin or clothes during operation, it should be washed clean with water in time. Due to the use of highly corrosive solutions, the operation process must pay attention to safety! 6. Circuit board drilling Circuit board is required by inserting an electronic information components, so for circuit board drilling is essential. The choice of drilling needles is based on the thickness of our electronic control components pin and decide, in the operation process drilling machine can be analyzed when drilling, must hold the circuit board, to maintain the speed of the drilling machine, can not open too slow. 7. Circuit board pre-processing The last step (drilling) will need to pre-process the PCB, will be covered in ink on the board with fine sandpaper to wipe off, and then in the water will be cleaned PCB. Circuit board on the water after drying, with rosin coated on the side of the circuit, you can use hot air to heat the circuit board to accelerate the solidification of rosin, only 2-3 minutes rosin can be solidified. 8. Soldering electronic components Here is the last step, all the electronic components are welded to the circuit board, power. At this point, the pcb board production process has been completed. But before the production of PCB, the need for simple and practical manufacturability design analysis tool to check the PCB design defects. Most engineers in the design process directly ignored the DFM analysis process, resulting in a large number of design pitfalls into the production side, ultimately leading to PCB board scrap, delayed development cycle, missed the opportunity to market the product and a series of problems. In order to help electronic engineers avoid possible problems in PCB design, standardize design criteria, improve design efficiency, promote enterprises to shorten R&D cycle and reduce manufacturing costs, it is a must-have desktop tool for PCB health doctors, PCB engineers, hardware engineers, PCB factories, SMT factories, and PCB traders. More than 200,000 engineers are currently using the practical manufacturability analysis software. Core Features: 1、Analysis and design of hidden problems 23 + items 2, warning of the impact of the market price for the project, and for the hidden problems and affect the price of the project to give the optimization of design solutions Support click to parse the fast board, PADS, Altium, Protel, Gerber file types 4. Multi-layer automatically match the stacked structure 5.Intelligent impedance tool, combined with production factors, impedance data calculation or back-calculation. 6.Personalized splicing board, spike activity rule board or shaped board, can add as well as stamp holes. 7, open and short circuit problem analysis (IPC network for analysis) A key to output production tools (Gerber, coordinate file, Bom list) |

|

|

|

|

|

|

| 实用资讯 | |

|

|

|

|

| 一周点击热帖 | 更多>> |

|

|

|

| 一周回复热帖 |

|

|

|

|

| 历史上的今天:回复热帖 |

| 2022: | 常委是怎样练成的? | |

| 2022: | 在历史的关键时刻,要为亚裔孩子发声! | |

| 2021: | 李云迪是谁,不至于比那个“路人皆知” | |

| 2021: | 不同智商的人出门就碰到傻逼的概率 | |

| 2020: | 司马南在世纪末的两次悬赏骗局 | |

| 2020: | 不动佛心咒 | |

| 2019: | 834、彭斯将于24日11点演讲;天地棋局 | |

| 2019: | 用数据分析三自一包是挽救了中国农业 | |

| 2018: | A critique of economic theory of cli | |

| 2018: | 露安适圆满成功的举办了千人瑜伽世界纪 | |