2015-02-27

【Aiden in English】

Motors are all around us. There are in cars, fans, blenders, and many other things. They make our lives simpler, but barely anyone wonders what motors are made of and how they work. We just ignore a crucial invention that helps us. In science class for the past few weeks, we have been studying and building different kinds of motors, such as the straw compass motor, the spinning coil motor, and the armature motor. All of these motors are used in our everyday lives, and this was the first time that I really looked into the simple machine that powered many things.

The straw compass is one of the simpler motors that our science class did. It used electricity, to make an electromagnet, or a magnet that runs on electricity. The electricity flowed through a circuit, or an unbroken path of an electric current, and flowed through a coil. The coil became magnetic, and it would attract or repel, or push and pull, any magnet that came close. Then, we stuck a magnet on both ends of a straw, balanced the straw on a cup, and moved the coil closer to the magnets. When we turned on the electricity by completing the circuit with a switch, the magnets spun. After a while, the straw slowed down to a stop with a magnet pointing towards the coil. Whichever face of the magnet pointed towards the coil, the coil had to be the opposite polarity, of north or south. With magnets, opposites attract, and similarities repel, and so north and south attract, and north and north and south and south repels. With the straw compass motor, to keep the straw spinning, timing the switch was crucial because we have to time when the correct polarity comes around. This motor was the hardest of the three, and many of us failed to make it work.

The second motor that we learned about was much easier, but if it didn’t work the first time, troubleshooting, or fixing, was hard. It was called the spinning coil motor, and sometimes, it was a pain in the butt. It had a cup to hold up the motor, and on top of the cup were two bare, brass wire arms. These arms were strapped to the cup by two rubber bands on opposite sides of the cup, and on the ends of the wires was an alligator clip with a wire twisted around it. Those wires were connected to a battery and a switch, making the circuit. The bare, brass wires were twisted in a loop on top of the cup, making an arm. Then, we took a red wire, wrapped it into a loop, and sandpapered the ends to take off the red insulator on the surface. By doing this, the electricity could flow through the wire. Place the loop between the arms and a magnet under the loop, and the loop would spin as soon as the switch was turned on. The coil spun because of the automatic switch, or the brass arms. The electricity went around the coil in circles, which made the coil spin.

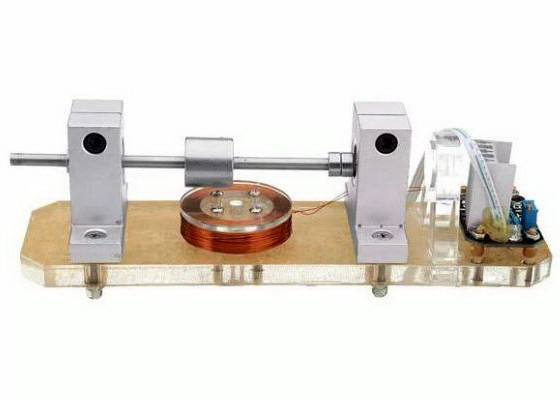

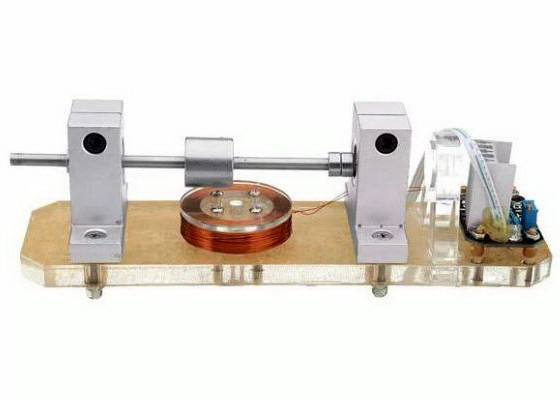

The armature really got the class’s attention. It used a part of a real motor in the center called the armature, hence the name. The armature has magnets attached to its sides, making it stick to some metals. There was a shaft sticking out one end, and on the other was a brass part called the commutator. We used the same setup as the spinning coil motor, but only with one brass arm. The other was a red and white wire taped together with electric tape and strapped to the opposite side of the brass arm. The exposed parts of the red and white wires were bent into the shape of a V. We placed the commutator on the V and placed the shaft on the brass arm. We turned on the switch, and when we moved a magnet near the armature, it spun with amazing speed. A whirring sound would fill the air, and we could make it spin faster or slower by either moving the magnets farther away or closer. Also, if we flipped the red and white wires, flipped the battery, or turned over the magnets, the direction of the spinning armature would change, forward or backward.

Motors are used in our everyday lives, yet as much as they are everywhere, we’ve grown so used to them that they just seem to become a part of our world. Our science curriculum on motors has really shown me what the machinery was in simple things and described how they work. With motors, the world seems as big as ever.

【红霞译文】

发电机应用广泛,汽车、风扇、搅拌机以及其它五花八门的机器都有马达装置。发电机虽让我们的生活变得更加便利,但极少有人对其制作和运转发生兴趣,因而忽略了一些至关重要的科技发明。过去几周的科学课上,同学们一直忙于学习组装几种不同形式的发电机,比如:吸管罗盘发电机、旋转线圈发电机、电枢发电机,日常生活离不开些发电机,我也是第一次接触这类结构简单而功能却又复杂的玩艺。

吸管罗盘发电机属于科学课上介绍的较为便捷的马达之一,有电的地方就有电磁场,即带电的磁场,电流通过电路板或者完好无缺的线圈使电线变成电场,当任何两个电场相遇,彼此不是相吸就是相斥,即所谓的推拉作用。我们在吸管两端各绑上磁铁,并吸管中央垫上一只杯子,这时再把线圈移近磁铁。等打开开关通电之后,磁铁靠磁力转起圈来;不一会儿,吸管渐停,磁铁指向线圈,无论磁铁哪一侧面对线圈,必定正负极相反,要么冲北要么朝南。就磁铁本身而言,异性相吸同性相斥,所以南北相吸,北对北或南对南相斥。欲要保持吸管不停地旋转,定时开关至关重要,只有这样才能确保整个罗盘的方向,正因如此,吸管罗盘发电机是三种发电机中最难掌控的,许多同学最终也未能操作成功。

我们学的第二个旋转线圈发电机相对比较容易,但头一回上手难度还是挺大,需要排除故障找出解决办法,有时真叫人着急上火。具体做法是,用一个杯子撑住马达,杯子顶端拴上两根赤裸裸的铜丝棒,铜丝棒的一端靠两条橡皮筋被固定在杯子两侧,另一端各有电线环绕的弹簧夹,弹簧夹连通电池及开关形成闭式电路。随后,我们把红色电线弯成环状正挂杯上,两头用砂纸打磨以去掉外部红色绝缘材料,这样电流通过电路就会畅通无阻。将铜丝棒之间接上金属线圈,线圈下放置磁铁,一旦打开开关,线圈立刻开始转动。线圈之所以旋转是因为自动开关即铜丝棒导电,电流通过线圈带动线圈旋转起来。

电枢可谓全班同学最为感兴趣的话题,其实它不过是整个电机的组成部分,电枢马达由此而得名。电枢的侧面极富磁性,只要碰到金属物质便自动粘在一起。电枢有一中轴,一端伸出体外,另一端带铜芯的部分叫换向器。大家按照旋转线圈发电机的操作方法将线路连接好,不过在这里只需要一根铜线就够了,红白电线先用隔缘胶带绑在一起固定到铜线末端,再将红白电线弯成V字形,然后把换向器放在V字形上。这时,我们打开开关,随着磁铁移近电枢,电枢飞快转动起来,由此发出惊天动地的鸣叫声。通过调整磁铁与电枢的距离,电枢的转速时快时慢;如果对换红白电线的位置,或者将电池倒一下方向,或者给磁铁翻个身,电枢的转向要么向前要么向后。

日常生活离不开发电机,发电机随处可见,并且早已渗透到各个角落。科学课发电机专题确实教我了解常见的机械化装置及其工作原理,由于发电机的存在,世界似乎变得越来越大。